Aquafeeds refer to any feed given to aquatic farmed animals as part of aquaculture. Fish (both farmed and wild) require a balanced mix of essential nutrients such as amino acids, fatty acids, and vitamins to thrive.

A key component of sustainable aquaculture is using feed ingredients that support sustainable growth of the aquaculture sector and preserve the unique combination of nutrients needed to sustain healthy fish and healthy people. With this in mind, scientific research has driven major improvements in the sustainability and efficiency of aquafeeds.

Arrow Machinery is committed to producing high-end aquatic feed production equipment and providing customers with comprehensive engineering services.

Feed Utilization: Due to the physical and chemical changes in the extruded process, the extruded feed generally produces powder within 1%, which directly improves the effective use of feed.

Digestion & absorption: Due to the high temperature and high-pressure processing conditions, the starch in the feed is well matured which is more favorable to digestion and absorption, and the fiber structure and cell wall are destroyed and softened, thereby improving the palatability and digestibility of the feed.

Water quality: The extruded floating fish feed will not dissolve in the water for a long time.

The observation regarding fish growth, feed requirement & feed intake habits

Wide range of feed size: Due to high pressure, temperature & moisture range we can get a wide range of feed sizes from the extruder die, ranges from 0.8 mm to 5 mm; as per fish growth & species.

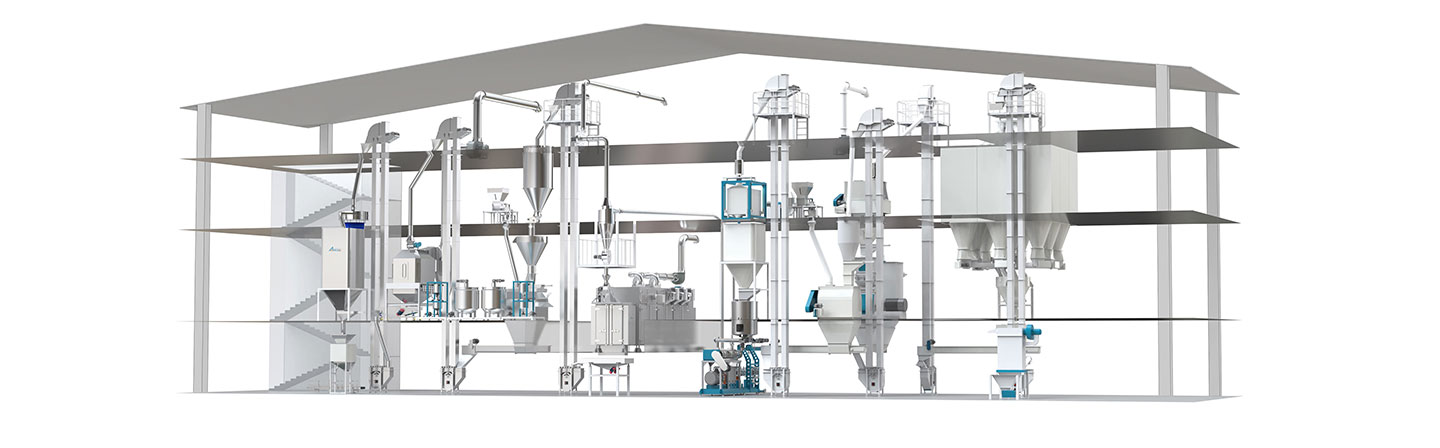

Arrow Machinery provide the turnkey solution for the Floating fish feed production line. Including the raw material receiving, automatic batching, grinding, mixing, extruding, drying, caoting, cooling and packing system.

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Heat exchanger is burned by gas or diesel burner. Hot air is sprayed by high pressure blower , which makes corn flakes puffed and bubbles instantly. Th...

Heat exchanger is burned by gas or diesel burner. Hot air is sprayed by high pressure blower , which makes corn flakes puffed and bubbles instantly. Th...

Vacuum spraying equipment is a new feed processing technology developed in recent years, which is mainly used for liquid addition or oil spraying to ex...

Vacuum spraying equipment is a new feed processing technology developed in recent years, which is mainly used for liquid addition or oil spraying to ex...

Shrimp feeds are among the most expensive diets within the aquaculture industry, largely due to their need for high water stability. Shrimp locate feed exclusively by smell and taste rather than sight. Unlike finfish, shrimp require minutes or hours to locate feed after it is distributed in ponds.

The extrusion process begins with preconditioning the meal using steam and water to form a hot, moistened mash. The mash is introduced into the extruder barrel and conveyed to the other end by a rotating screw which creates heat due to friction. The feed exits the extruder barrel through a restricted die opening that creates pressure and forms the desired shape. The extrudate strands emerging from the die are cut into pellets with a rotating knife. The process has flexibility to produce diets with a wide range of fat levels, densities, shapes and sizes.

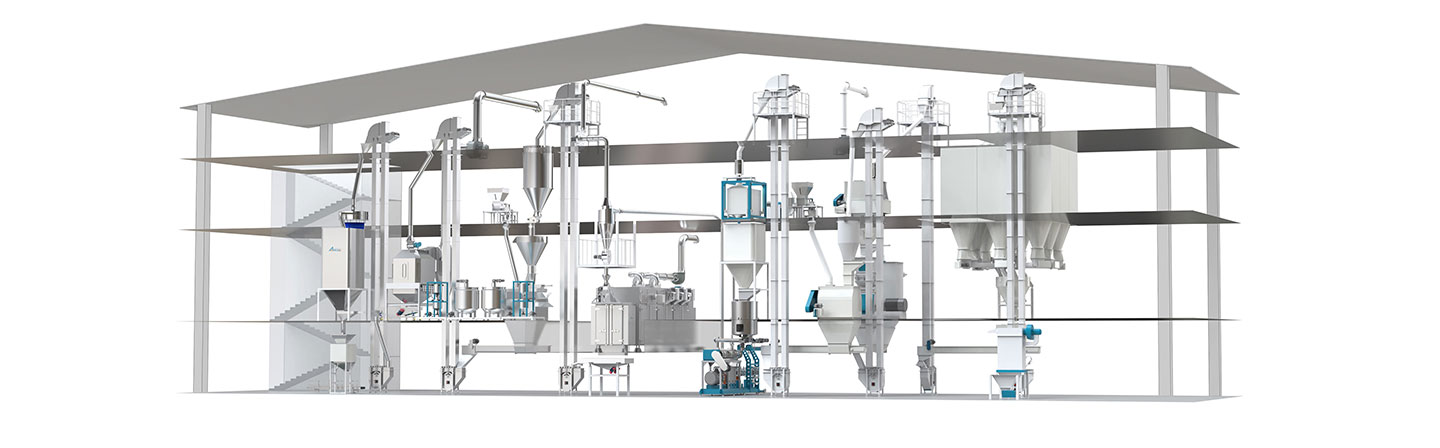

Arrow Machinery provide the turnkey solution for the Shrimp and crab feed production line. Including the raw material receiving, automatic batching, grinding, mixing, extruding, drying, caoting, cooling and packing system.

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Heat exchanger is burned by gas or diesel burner. Hot air is sprayed by high pressure blower , which makes corn flakes puffed and bubbles instantly. Th...

Heat exchanger is burned by gas or diesel burner. Hot air is sprayed by high pressure blower , which makes corn flakes puffed and bubbles instantly. Th...

Vacuum spraying equipment is a new feed processing technology developed in recent years, which is mainly used for liquid addition or oil spraying to ex...

Vacuum spraying equipment is a new feed processing technology developed in recent years, which is mainly used for liquid addition or oil spraying to ex...

Sterlets, carp, tench and rudd are just a few of the fish species that we class as bottom-feeding fish since they prefer to eat food from the depths of the pond that they inhabit. Sinking pellet food is specifically designed to accommodate these fish and therefore generally dense in its formulation so that it does not float on the water's surface.

Sinking pellet fish food is a fast-sinking highly digestible food that considers the natural eating habits and unique dietary requirements of fish species that prefer to feed on lower levels of the pond.

The highest quality, most premium pond foods tend to be in pellet form. Sinking pellets don't blow away in the wind like flakes and tend to pack more actual food per volume, making them popular with pond keepers who need to feed a lot to keep their fish growing.

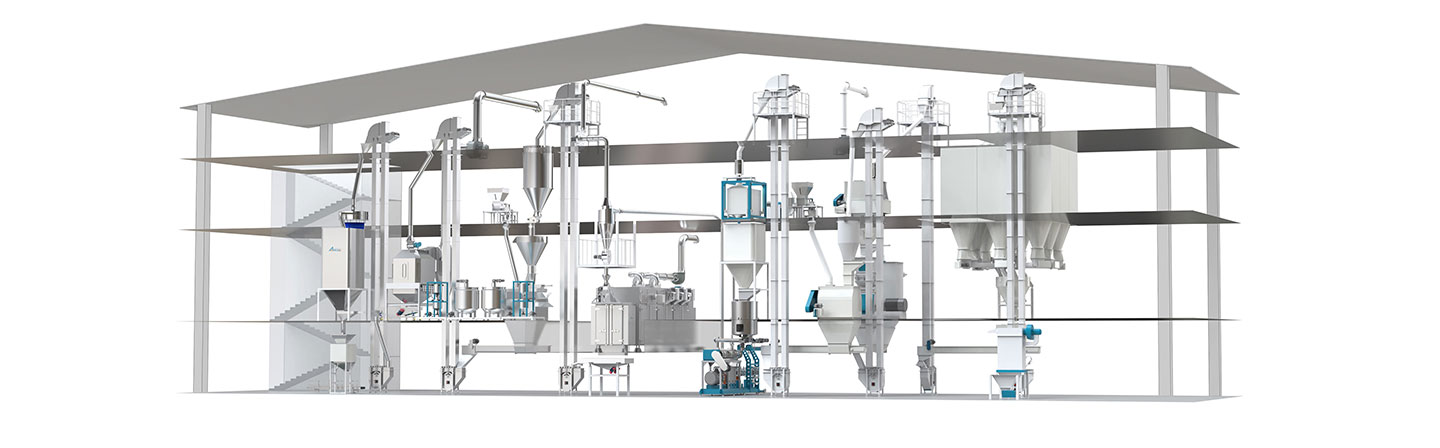

Arrow Machinery provide the turnkey solution for the Sinking fish feed production line. Including the raw material receiving, automatic batching, grinding, mixing, extruding, drying, caoting, cooling and packing system.

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Extruder is the core machine, which ensure the best extruding and cooking effect.

Extruders of Shandong Arrow are designed by 3D soft...

Vacuum spraying equipment is a new feed processing technology developed in recent years, which is mainly used for liquid addition or oil spraying to ex...

Vacuum spraying equipment is a new feed processing technology developed in recent years, which is mainly used for liquid addition or oil spraying to ex...

Double drum spraying machine is mainly used for the mixing of seasoning powder in the late stage of food processing or the coating of raw materials and...

Double drum spraying machine is mainly used for the mixing of seasoning powder in the late stage of food processing or the coating of raw materials and...

Technical Support: Yandex