Breakfast cereals corn flakes have become firmly established on breakfast tables almost all over the world. In addition to a wide variety of forms, tastes and colours, they are expected today to also meet stringent nutritional quality requirements. A consistently high product quality, high operating reliability, and maximum efficiency are the most important requirements that state of-the-art production systems must satisfy.To meet them, Arrow offers its customers a multitude of suitable system components plus the relevant expertise in plant design and construction and in process engineering.

Benefits of corn flakes, the major ingredients include milled corn, sugar, iron, high fructose corn syrup and vitamins (A, B, C, D, and E). Corn flakes are very rich in thiamine. Thiamine is good for carbohydrate metabolism, energy production and cognitive functions. Even though corn flakes are not rich in fiber, it can easily be taken care of by adding fresh fruits and nuts to your bowl of corn flakes. Corn flakes are a packaged cereal product formed from small toasted flakes of corn, and are usually served cold with milk and sugar. Since their original production, the plain flakes of corn have been flavored with salt, sugar and malt, and many follow-on products with additional ingredients have been manufactured such as “sugar frosted flakes”, “honey nut corn flakes” and others.

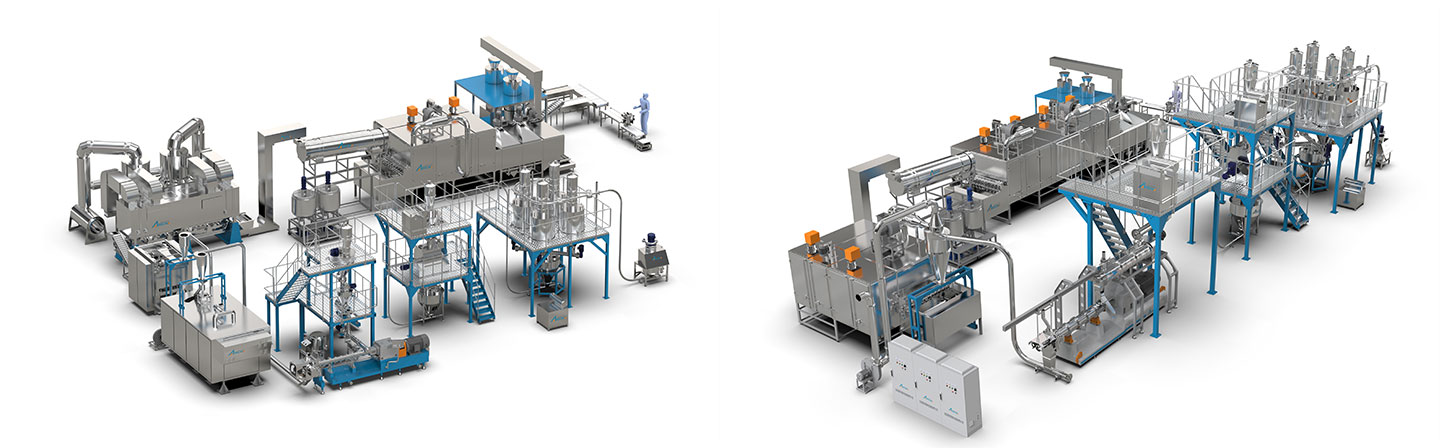

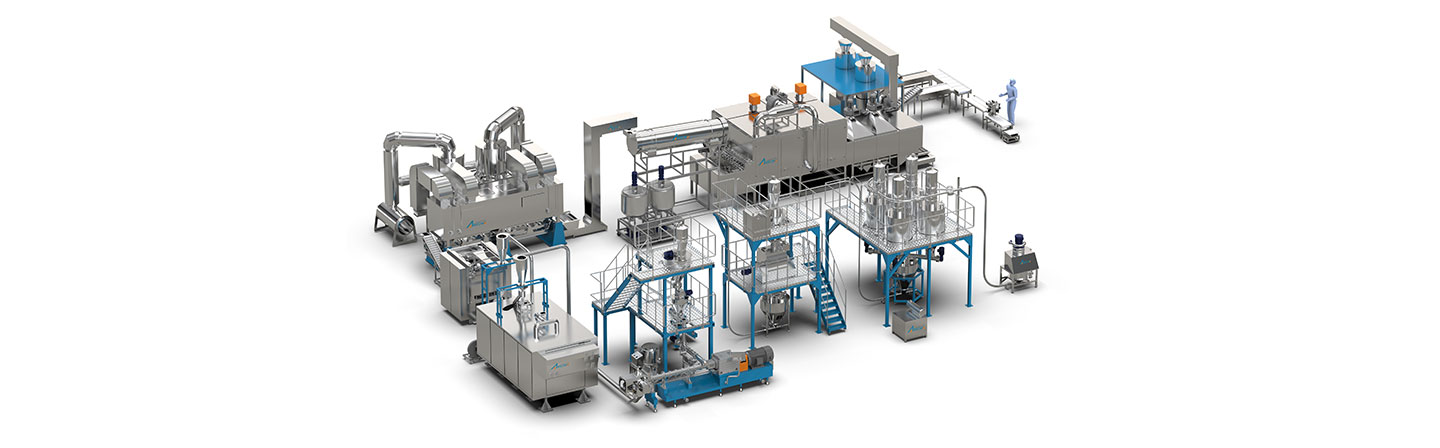

Arrow Machinery provide the turnkey solution for the Breakfast cereals production line. Including the Flour mixing, Extrusion, Pre-drying, Flaking, Hot air roasting, Coating, Drying, Cooling, Packing system.

Water drop type pulverization machine adopts direct drive, scientific and reasonable hammer-screen gap, change the gap, can be coarse, fine crushing, c...

Water drop type pulverization machine adopts direct drive, scientific and reasonable hammer-screen gap, change the gap, can be coarse, fine crushing, c...

Single shaft blade mixer, suitable for mixing granule and powder, granule and granule and adding a small amount of liquid, applied to nuts, beans, feed...

Single shaft blade mixer, suitable for mixing granule and powder, granule and granule and adding a small amount of liquid, applied to nuts, beans, feed...

Double shaft blade mixer is also called the gravity mixer, can be roughly divided into two categories one is a common gravity mixer, a flying knife typ...

Double shaft blade mixer is also called the gravity mixer, can be roughly divided into two categories one is a common gravity mixer, a flying knife typ...

Breakfast cereals are processed grains for human consumption, typically packaged for sale as either ready-to-eat (RTE) or hot cereals (HC), requiring cooking before consumption. RTE cereals are produced by sequential operations of cooking, shape forming, and drying, with subsequent options of flavorings, sweeteners, vitamin and mineral fortification, and particulate additions before packaging. Flaked, puffed, shredded, and extruded RTE cereals are made from whole grains or parts of grains of corn, wheat, rice, or oats. The major HC are rolled oats in various forms, farina and other wheat fractions, and corn grits. All are marketed in packaging that is both protective and able to display the product's nutritional and sensory merits.

Arrow Machinery provide the turnkey solution for the Breakfast cereals production line. Including the Flour mixing, Extrusion, Pre-drying, Coating, Drying, Cooling, Packing system.

Features:

1. External air circulation, high thermal efficiency.

2. Bottom heating box.

Features:

1. External air circulation, high thermal efficiency.

2. Bottom heating box.

Cross circulation efficient dryer

Application: pet food, and plant protein TVP

Adopt hot air circulation ...

Cross circulation efficient dryer

Application: pet food, and plant protein TVP

Adopt hot air circulation ...

Heat exchanger is burned by gas or diesel burner. Hot air is sprayed by high pressure blower , which makes corn flakes puffed and bubbles instantly. Th...

Heat exchanger is burned by gas or diesel burner. Hot air is sprayed by high pressure blower , which makes corn flakes puffed and bubbles instantly. Th...

Technical Support: Yandex